Revolutionary Invention Makes Turning a Nut Obsolete

Like microwave ovens and personal computers, every once in awhile an invention so profound and life changing alters the world. The bolting industry is lucky enough to gain an invention of the same caliber, the ZipNut.™

A revolutionary concept in threaded connections; ZipNuts replace the time-consuming and repetitive motion of threading regular nuts and replace it with unparalleled speed and accuracy.

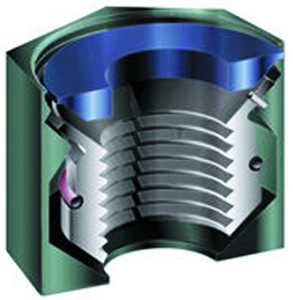

ZipNuts simply slide over the threaded portion of a fastener in one motion and with a quick turn to tighten it, reduce fastening time to a fraction of what it takes a regular nut. This is possible thanks to a specially designed housing where the ZipNut’s three, spring-loaded thread segments expand as they travel down the bolt.

ZipNuts simply slide over the threaded portion of a fastener in one motion and with a quick turn to tighten it, reduce fastening time to a fraction of what it takes a regular nut. This is possible thanks to a specially designed housing where the ZipNut’s three, spring-loaded thread segments expand as they travel down the bolt.

When the ZipNut is tightened with a quick turn, those same thread segments are forced into the threads of the bolt thanks to the complementary geometry between ZipNut’s housing and its thread segments.

ZipNuts fit standard bolts but are customizable to fit any thread type. With performance that is equal to ASTM A194-2H nuts, ZipNuts run down corroded, painted and damaged threads without hesitation.

Cross threading is just a distant memory with the ZipNut because of its spring-loaded thread segments that expand and allow ZipNuts to run down past any problem areas. They even come in a Double ZipNut option that allows users to slide the ZipNut off a threaded stud just as easily as they slid it on.

Why is ZipNut so revolutionary? Well, like memory foam, cordless tools and water filters, ZipNut was originally developed for NASA for use on the Space Shuttle, International Space Station and Hubble Telescope. Thankfully, the bolting industry benefits from the solutions NASA found for its challenges.

Currently available to energy, nuclear, fire/rescue, aerospace, tooling and medical industries, ZipNuts return the initial investment for this revolutionary technology in a very short time.

Produced in different sizes and materials, including stainless steel, nickel-plated and additional corrosion coatings, ZipNuts measure one size larger across the flats than heavy hex nuts.

If you want to take the tedious repetition and time-consuming task associated with standard threaded nuts, it’s time to make ZipNuts your solution. Check out a video on ZipNut and ZipNut Technology at http://www.youtube.com/watch?v=k28DdqVuqQc.

Next week’s blog will take a look at how the ZipNut Technology is changing the face of several industries through innovative tool adaptations, including energy and nuclear, to improve safety, speed and accuracy.

FASTORQ is the exclusive manufacturer of ZipNut Technologies for the energy and exploration industries. FASTORQ’s innovative use of ZipNut Technology in several of its tools has increased speed, reliability and worker safety in such areas as oil exploration and production, subsea applications, nuclear energy maintenance and more.

ZipNUT is a registered Trademark of ZipNut Technology, LLC

AUG

About the Author:

Lisa Raynor-Keck is the Marketing Communications Specialist at FASTORQ. She earned her degree in journalism from the University of Central Florida and gained her early writing experience at newspapers in Michigan and Tennessee. In addition to her press positions, Lisa's work portfolio includes experience as a freelance writer, political campaign ad designer and public relations professional. She also has experience working as an editor and writer for the technology division at Middle Tennessee State University and an articles editor for the Navy's former online military lifestyle website Lifelines. Lisa is currently studying to earn her M.A. in corporate communication at Austin Peay State University.